Innovative "weaning ramp" improves productivity, animal wellbeing

Date posted: January 12, 2023

Two employees of HyLife sow farms in La Broquerie Manitoba have won the F. X. Aherne Prize for Innovative Pork Production at the 2023 Banff Pork Seminar (BPS).

Robert Lafrenière and Barak Doell developed what they have called the "HyLife weaning ramp", an innovation that improves working conditions, animal well-being and productivity. They were presented with their award in front of conference delegates by Ben Willing chair of the Seminar awards committee.

"Each year our committee is impressed by the innovation of people in our industry who enter our competition," says Willing. "The award can be for any innovation and it comes with financial reward in the form of a ticket to the Seminar for two people and support for travel costs to attend. However, the biggest prize for many is the recognition by industry peers for their efforts."

The weaning ramp designed by Lafrenière and Doell is a solid example of the goals of this competition, says Willing. "Grassroots innovation built with team support and an idea that helps others in the industry in their daily work. Frank Aherne, who was a professor at the University of Alberta and a major force for science-based progress in the Canadian pork industry, would be proud."

In their own words Robert Lafrenière and Barak Doell describe the invention. They say it is an extension of the fact that HyLife is deeply committed to animal welfare. Respecting both pigs and employees is a company core value. This is an innovative improvement in company farm operations.

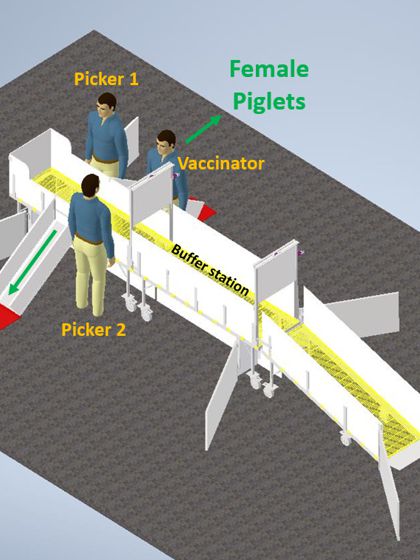

In most sow farms, the weaning process typically involves picking up piglets, vaccinating them and separating by male and female.

To accomplish this, staff will pick up piglets from the floor, bring them to the person performing the vaccination, and finally, put them on the appropriate side of the hallway depending on their sex.

Repeatedly collecting and picking up piglets places strain on a worker's body, especially their back and arms, as most of these piglets are either 12 lbs. or heavier. Staff often consider this process one of the most labor-intensive and strenuous tasks at a sow farm, with some farms weaning 3,000 piglets per week.

To improve this method and reduce worker strain and stress for piglets, HyLife designed an innovative weaning ramp that eliminates the need to pick up piglets off the floor. The process is as follows:

- Initially, piglets exit the farrowing crate by opening the sow gate while staff use noise shakers to move them into the alleyway and towards the ramp.

- Piglets are moved up the ramp in groups of 20 to 25 depending on the ramp size (bigger farms have larger ramps).

- Once up the ramp, a gate using a pulley system is lowered behind the piglets and staff can begin picking the piglets from waist height to be vaccinated and then place them on a slide depending on their sex.

- Gradual sloping slides off each side of the station bring the piglet back down slowly and gently to ground level.

HyLife has implemented weaning ramps at multiple sow farms, all of which have been received very positively by staff due to the significant ergonomic improvement. Of equal importance, the weaning ramp reduces stress on the joints of the piglets by minimizing the amount and degree they are handled by workers.

Most of HyLife's sow farms have different layouts and space available; our team has developed assorted ramp designs depending on what works best for a specific location. HyLife is in the process of successfully implementing the weaning ramp in all its sow barns.

Perhaps the best indication of the value of this innovation are comments that come from HyLife barns. This one is from a HyLife manager on a larger operation. "Using the weaning ramp saves your back! It is a big improvement on health and safety for the workers because it eliminates bending to pick up piglets off the ground. It also improves the quality of vaccination for the piglets."

And another site manager adds, "Teammates are very happy with the ramp. Less stress for both piglets and workers."