The stories behind the 2020 Banff Pork Seminar Aherne Innovation Prize winners

Date posted: January 9, 2020

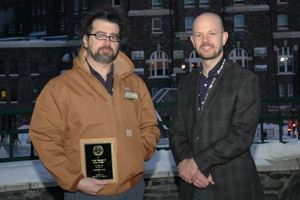

Ben Willing (left) and winners Gillian Greaves (center) and Tess Faulkner South West Ontario Veterinary Services.

It is always a highlight of the Banff Pork Seminar and this year the response was no different as two well-designed innovations, one from Canada, one from the U.S., shared the honours as winners of the F. X. Aherne Prize for Innovative Pork Production at BPS 2020, Jan. 7 to 9 in Banff, Alta.

Winners for their Hammock Swine Restraint Device were Tess Faulkner and Gillian Greaves of South West Ontario Veterinary Services in Stratford, Ont. Winners for their FarrPro Haven micro-climate for pigs were Amos Petersen and Chris Hansen of FarrPro Inc. in Iowa City, Iowa. The awards were presented by Ben Willing, University of Alberta, chair of the F. X. Aherne Prize committee.

The Hammock restrains the pig to allow both the operator and the animal to relax. Instead of using a sorting board or their body to restrain the animal, animal care staff is able to place the piglet into the restraint, keeping both hands free to safely operate euthanasia devices such as a captive bolt gun, ensuring accurate placement of devices.

FarrPro's Haven unit is a heat and light supplementation platform for use in farrowing crates. It creates draft free microclimate chambers allowing it to deliver highly efficient heat energy to two separate litters. It promotes healthy creep behavior while significantly reducing pre-wean mortality and energy use.

"The Aherne Prize recognizes individuals who have developed either original solutions to pork production challenges or creative uses of known technology," explains Willing. "There is no better place to celebrate industry innovation than the Banff Pork Seminar and we are pleased to acknowledge grassroots inventiveness in the pork industry."

The late Frank Aherne, a professor at the University of Alberta, was a major force for science-based progress in the Canadian pork industry.

Here are the stories behind the two winners edited from their presentation background.

The FarrPro Haven: A Perfect Micro-Climate for Newborn Pigs

The pre-wean mortality rate (PWM) in the swine industry is at unprecedented levels and continues to cause major economic and productivity losses. Iowa based ag tech startup FarrPro has developed novel approach to address this ongoing and costly problem.

FarrPro's patent pending Haven unit is a heat and light supplementation platform for use in farrowing crates. Using the divider wall between neighboring creeps as a base, the Haven creates a draft free microclimate allowing it to deliver highly efficient heat energy to two separate litters. Its elongated, semi-enclosed design provides over 4 cubic feet per creep of controllable and consistent heat energy which promotes healthy creep behavior while significantly reducing pre-wean mortality (PWM) and energy use.

Iowa State University's Agricultural and Biosystems Engineering department recently completed a pilot study of Haven units on a commercial farrowing farm in Ogden, Iowa. The result of that study showed a significant reduction in PWM from 12.04 percent in heat lamp litters compared to 9.67 percent in Haven litters, a 20 percent reduction. With the U.S. average born-alive litter size being approximately 13.5, this translates into 0.32 more pigs weaned per litter. The study also showed that Haven units used an average of 3.25 kWh per day compared to the heat lamp average of 6 kWh per day, a 46 percent reduction in energy use.

Scott Dorr, farrowing manager for the Ogden, Iowa producer where Iowa State conducted the study, has this to say about the Haven units.

"With over 30 years in the hog business I've never seen pigs lay as comfortably as they do under the Haven. They're warm, relaxed, and there's no piling. But what's really amazing is how well they spread out along the divider wall between stalls which reduces the chance they will be laid on. Because of this, the Haven significantly reduced our overall pre-wean mortality rate when compared to heat lamps and also used 46 percent less energy to operate so they are helping us deliver more healthy pigs to the nursery while lowering our energy costs. That's a win-win for us."

In July of 2019, FarrPro's Haven was selected by a panel of industry experts as one of the swine industry's top new products in the 2019 National Hog Farmer New Product Tour and also won the National Hog Farmer's "Producer's Choice" Award.

The Hammock restraint device improves animal care and handling

As young professionals starting out in the swine industry, we were quickly immersed in on-farm production as well in on farm trials in conventional swine facilities. These environments often accommodate the typical farmer, someone who is strong and has years of experience handling pigs.

In contrast, we entered this field, with less experience, so we found that there was a need to create something to help in our daily working lives when it came to having to restrain pigs. Although nursery pigs are small, when you are learning new techniques, especially ones that have to do with euthanasia, it can be difficult to restrain them comfortably.

One thing that we had to do in our research trials as well as when helping production clients was euthanize piglets in nursery settings. Although a producer may find this task simple enough, our physical ability and lesser experience led us to try and find a new way to complete the same task. So we developed the Hammock.

Our research and production team is made up largely of newcomers to the swine industry and we were able to use our tool in helping with euthanasia training of new staff members, as well as with producers who, although experienced, also expressed difficulty when having to handle pigs and euthanize.

Depending on the size or fitness of the animal, as well as the size or fitness of the personnel who had to complete the euthanasia, the process could become quite difficult, causing unnecessary stress to both the animal and the human handler.

Better restraint

The Hammock acts to restrain the pig in a manner that allows both the operator and the animal to relax. Instead of using a sorting board or their body to restrain the animal, animal care staff is able to place the piglet into the restraint, keeping both hands free to safely operate euthanasia devices such as a captive bolt gun, ensuring accurate placement of devices.

In addition to increased human safety, the Hammock relieves the pressure placed onto the pig with traditional restraint methods, decreasing the amount of stress that the animal is placed under in restraining practices associated with euthanasia.

Device specifications

The Hammock was designed to be practical - easily compactable, folding down to be stored and used in a barn setting. A number of variations were constructed and tested in a barn setting with both research staff and producers. The latest design has improvements in strength, collapsibility, ease of cleaning, as well as the ability to use with pigs of various sizes (from 5kg to 25kg).

In addition, this design can be easily built by producers for a minimal cost using items found at a local hardware store.